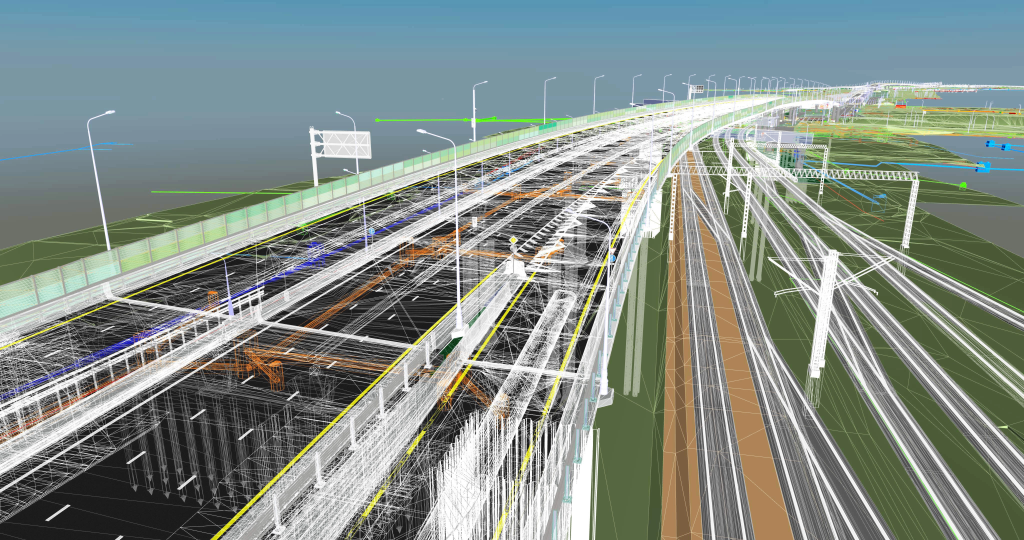

Introduction

1. Enhancing Multi-Disciplinary Collaboration

- Improved Communication: BIM’s real-time data updates allow engineers to collaborate on a shared model, preventing discrepancies between different systems. According to the National Institute of Standards and Technology (NIST), inadequate interoperability between project stakeholders results in an annual loss of $15.8 billion in the U.S. construction industry (Gallaher et al., 2004). BIM directly addresses these inefficiencies by integrating data flow across disciplines.

- Clash Detection: BIM’s ability to detect clashes early in the design phase helps resolve conflicts between systems, such as electrical and plumbing, before construction starts. A study by Dodge Data & Analytics found that BIM can reduce design errors during construction by up to 55% (Dodge Data & Analytics, 2018).

Real-World Example: Multidisciplinary Coordination in Healthcare Projects

A hospital construction project in the UK, which utilized BIM to coordinate mechanical, electrical, and plumbing systems, saw a 35% reduction in clashes compared to traditional methods (Bryde et al., 2013).

2. Improving Design Accuracy and Structural Integrity

- Structural Analysis: BIM enables engineers to simulate structural loads, stresses, and dynamic forces, improving the reliability of their designs. A report by McGraw Hill Construction reveals that 78% of structural engineers experienced fewer errors in load-bearing calculations after adopting BIM (McGraw Hill Construction, 2014).

- Precise Material Quantification: BIM’s precise modeling also extends to material quantification. The American Society of Civil Engineers (ASCE) found that using BIM can reduce material waste by up to 15%, as engineers can accurately calculate the required quantities of construction materials (ASCE, 2013).

Case Study: Load Simulation in Bridge Construction

A compelling example of BIM’s impact on bridge construction is the Grandfather’s Bridge project in Helsinki, Finland. This project utilized BIM to enhance coordination and efficiency throughout the construction process, particularly in scheduling tasks related to steel fabrication, concrete pours, and timely deliveries. By integrating BIM from design to construction, the project significantly reduced errors and the need for rework, resulting in substantial time and resource savings (Tekla, 2021).

Similarly, the Randselva Bridge in Norway, notable for being the longest bridge built without traditional drawings, exemplifies the advantages of BIM in managing complex structures. Through effective collaboration among teams across four countries, BIM facilitated accurate design and construction while minimizing waste, labor costs, and deviations from the plan. Both cases illustrate how BIM optimizes load simulations and material usage in bridge projects, leading to cost savings and increased project efficiency (BIM Community, 2020).

3. Streamlining Workflow and Efficiency

- Task Automation in BIM: In the Vico Workflow case study for a hospital project, the implementation of 5D BIM significantly streamlined processes by automating quantity takeoffs and scheduling tasks. This automation reduced manual labor and enhanced efficiency, contributing to shorter project timelines. Similarly, during the Oslo Airport Expansion Project, BIM tools enabled real-time access to centralized models, allowing contractors to automate repetitive tasks, which improved collaboration and reduced errors, resulting in a 25-30% decrease in project durations(Autodesk, 2017).

- Design Iteration and Flexibility: Engineers can quickly modify designs within BIM. Changes made to one part of the model automatically update the entire project, allowing faster decision-making and improved project outcomes.

Example: Infrastructure Projects

KPMG’s 2016 Global Construction Survey reports that firms using BIM on large infrastructure projects achieved a 22% increase in productivity (KPMG, 2016).

4. Cost Savings and Minimizing Waste

- Cost Reductions: A report by Deloitte highlights that BIM can reduce total project costs by up to 20%, mainly due to better coordination, fewer errors, and reduced rework (Deloitte, 2017).

- Material Waste Reduction: BIM helps engineers minimize material waste through accurate estimation and clash detection. The Waste and Resources Action Programme (WRAP) reports that using BIM in construction reduces waste by 15% (WRAP, 2013).

Example: Industrial Plant Construction

In an industrial project in Germany, BIM reduced construction costs by 10% and decreased waste by 25% through the optimized routing of pipes and materials (Eastman et al., 2011).

5. Enhancing Safety and Risk Management

- BIM platforms play a crucial role in enhancing safety and risk management in construction projects. For example, they allow for real-time hazard identification and safety monitoring throughout a project’s lifecycle, ensuring that safety concerns are addressed during the design, construction, and maintenance phases. According to Björkman et al. (2022), BIM facilitates better visualization of potential safety hazards and improves collaboration between stakeholders, leading to more efficient risk mitigation strategies. This proactive approach has significantly reduced the likelihood of workplace accidents and enhanced overall project safety.

- Regulatory Compliance: BIM also helps engineers integrate local building codes and safety standards into their designs. This ensures that all aspects of the project meet regulatory requirements, reducing the risk of costly rework or penalties.

Example: Fire Safety in High-Rise Buildings

A high-rise building project utilized Building Information Modeling (BIM) to simulate emergency evacuation procedures. This approach involved creating a 3D model of the building using 2D cadastral data, which allowed for detailed simulations of smoke emission and movement through various paths such as doors, windows, and stairwells. The simulations also considered the behavioral and physical characteristics of occupants during evacuation. As a result, the project achieved improved safety compliance and optimized the placement of stairwells and other critical evacuation routes (Taleai, Mokhtari, & Zlatanova, 2022).

6. Promoting Sustainability in Engineering Projects

- Energy Performance Analysis: BIM allows engineers to simulate and optimize a building’s energy performance. Research demonstrates that BIM-based simulations can optimize energy consumption and improve overall energy efficiency (Optimising Energy Performance of an Eco-Home using BIM, 2022).

- Supporting LEED Certification: Engineers can use BIM to track sustainable practices and streamline the process for obtaining LEED certification. A comprehensive framework shows how BIM can simplify the documentation process and enhance sustainable design strategies (Integrating BIM Processes with LEED Certification, 2023).

Example: Sustainable Design in a University Project

A university building project in Canada achieved LEED Gold certification, largely due to the energy savings enabled by BIM’s performance analysis features. For instance, McMaster University’s Engineering Technology Building, which incorporates advanced energy-saving features such as a heat recovery system and high-performance curtainwall system, achieved a 35% reduction in energy consumption (McMaster University, 2010).